Quality

That is unlikely to be matched

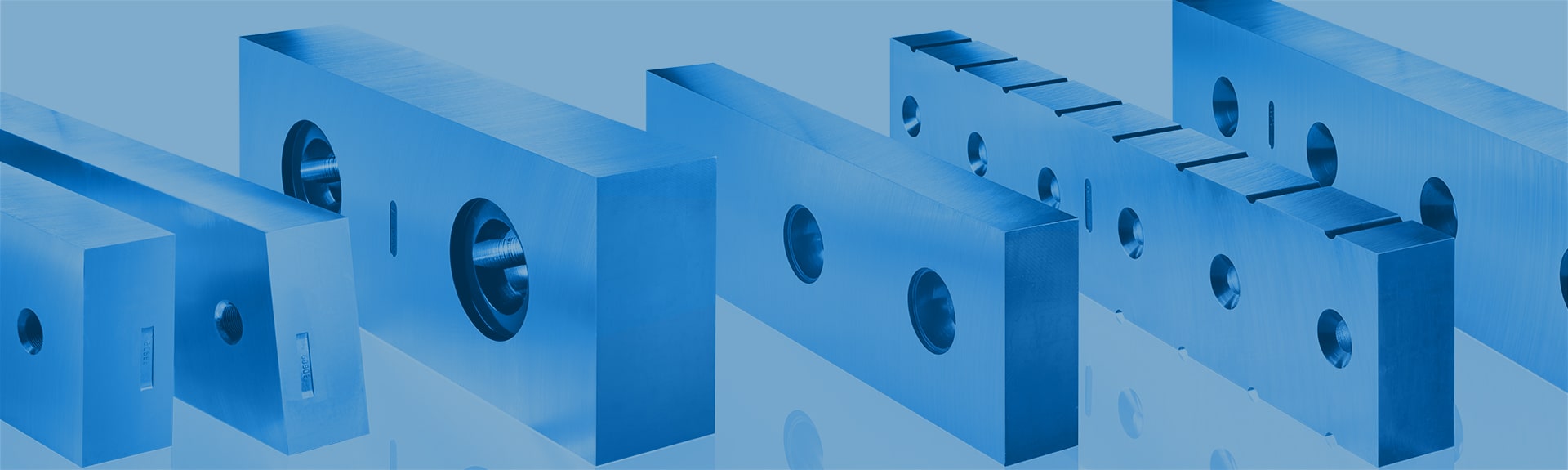

The blades and pressing tools are crucial for the service life and availability of scrap shears and briquetting presses. They must be made of an extremely robust material.

ETM eurotools uses only nickel-based super alloy tool steel. In addition, we cut the steel to size in our own production facility. This is followed by machining. The component is ready for shipment after a specific heat treatment and the fi nal grinding process.

Though this sounds comparatively easy, it requires a high degree of know-how and experience.

Our objective is to provide you with scrap shear blades, hammer pins and pressing tools that offer long-term reliability. This allows you to make optimal use of your systems and achieve maximum added value

Fast reaction

Our formula for emergencies and special cases:

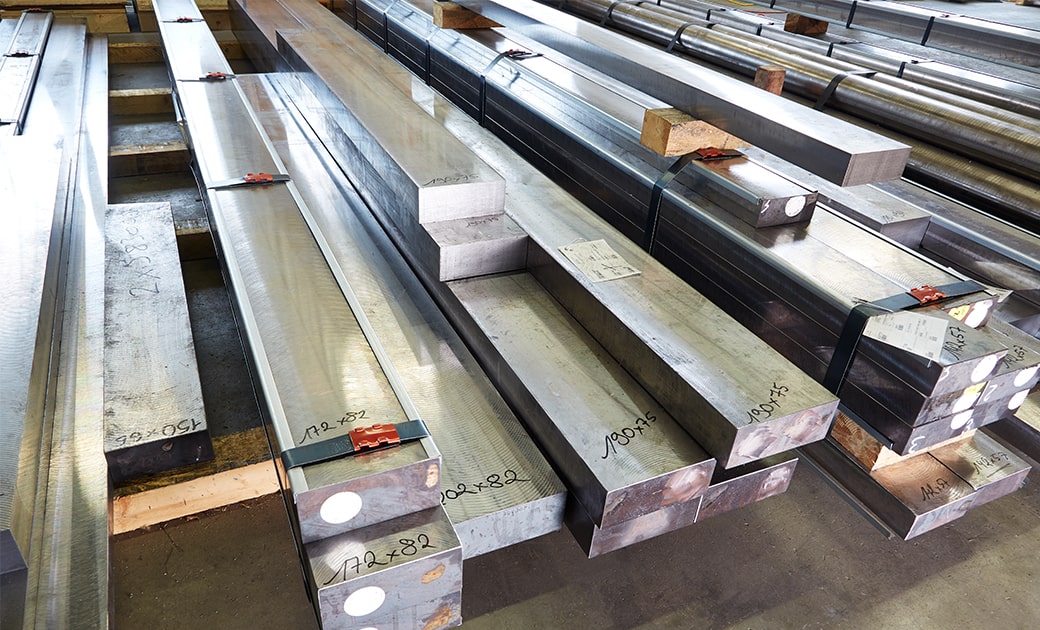

Since we make our own components, we can also respond quickly in the event of an emergency. The fact that we have our own steel stock is a major advantage:

In case of urgent orders we have direct access to high quality steel without long order and delivery periods.

This is immediately followed by further processing of the required component. For custom-made parts – whether in regard to hardness, dimension, shape, phase or fastening (e.g. different holes/counter bores for DIN bolts) – you can also rely on our word. Discarded delivery promises? Not with us!

Even if everything runs according “to plan” in day-today business, you benefi t from the fact that we leave nothing to chance, not even logistics: Within a 100 km radius from our location we perform deliveries with our own vehicles; for larger distances we work with international forwarding partners.